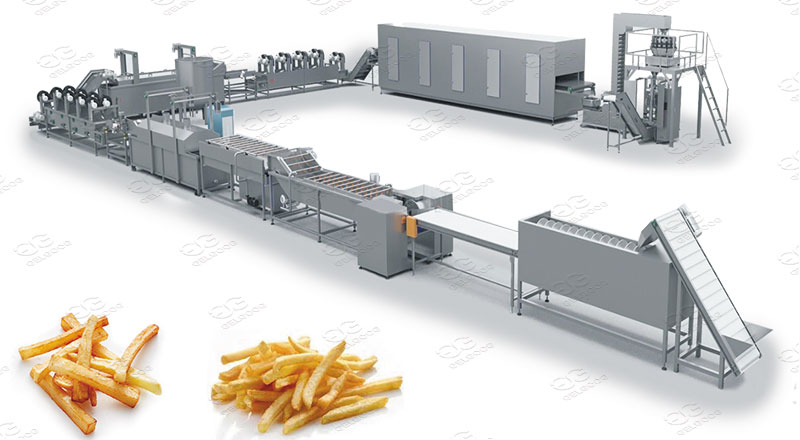

French fries production line for sale in Gelgoog. The French fries plant, also known as potato strips making plant, is a complete process line for manufacturing potato French fries out of potatoes. Like potato chips, French fries are also popular snacks for people around the world. So it is a profitable business opportunity to operate a French fries processing line. Each piece of equipment in Gelgoog is made to meet high quality as well as sanitation standards. And the French fries line can be customized to meet customers’ specific needs. Equipped with professional knowledge and rich experience, we are dedicated to offering your added value of the processing line with quick return. Contact us to find out the prefect solutions for your business.

Process and Machinery of French Fries Production Line

- Sorting. The first stage of the plant is to sort and choose quality potatoes, which determine the quality of end product. For the sorting process, there is sorting machine which can automatically choose the good ones while reject the bad ones.

- Washing and peeling. To ensure the good taste of French fries, the potatoes should be washed thoroughly, washing away soil and stones. And then the cleaned potatoes will peeled, ensuring uniform high quality of final product. As for our washing and peeling machine, it can wash and peel the potatoes in one machine, which can reduce costs of buying two machines separately. Our washing and peeling machine can wash and peel the potatoes carefully. As a result, you will get clean peeled potatoes without too much damage.

- Cutting. The peeled potatoes are fed into potato cutting machine, cutting the potatoes into desirable strips with adjustable thickness, length and thickness. French fries cutting machine can accurately cut the potatoes into regular shape strips with adjustable thickness.

- Blanching. This process can remove the excess starch on the potato strips. And it can also protect the strips from changing into undesirable color. The French fries blanching machine, equipped with temperature and time settings, will boil the strips for short period of time. It will wash off excess starch, preserve the desirable color, ensuring the good quality of end product.

- Dehydrating. After blanching, the potato strips should be dried, so that they will become crispy after being fried. This dewatering machine is installed after the blancher so as to dry the water on the blanched potato strips. As for drying machines, there are vibration dryers and dryers with fans. The drying machines can dry the potato strips evenly, ready for frying process.

- Frying. In the frying process, the potato strips are evenly fried in the French fries fryer with constant high temperature for a set period of time, resulting in golden French fries. There are three kinds of French fries fryers , such as basket type commercial fryer, continuous frying machines and batch type French fries fryer. These fryers can be used for different requirements. Whatever kinds you want, our frying machines can fry the materials evenly with good result. Except that, we also take the efficient use of oil and water into consideration.

- De-oiling. After the frying process, there is still oil on the surface of French fries, which makes the fries not crispy. So the fries should be de-oiled. And de-fatting machine can do this work in an effective and efficient way.

- Seasoning. This process can add favorable flavors to the fries, making them more tasty. Our flavoring machine can add flavoring powder thoroughly and evenly on the French fries, by rotating continuously.

- Packaging. The end of French fry making process is to pack the fries so that they can be stored for longer time and also can be transported easily. Our french fries packing machine can pack automatically according to your needs and requirements.

French Fries Process Lines in Gelgoog

To meet customer’s various requirements, we offer various turnkey customized solutions for French fries making businesses. In general, there are automatic French fries production line with fully automatic machines, semi-automatic processing line with both machines and manual operation. As for capacity, the automatic production line can produce large quantity of French fires, while the semi-automatic one produce smaller fries. When it comes to the end products, there are processing plants for packaged French fries, which can be sell to supermarkets directly. Besides, there are also production lines for frozen French fries, which can be sold to restaurants. whatever your needs, you can always reach us for help. With both experience and professional knowledge, we can offer tailored solutions for your French fries manufacturing businesses.

French Fries Plant Cost

The costs of French fries line are determined by several factors, such as raw materials, fees of licence location acquisition, labor costs and costs of French fries production machines. And the costs of machines can be a large part of total costs. As mentioned above, there are different kinds of French fries production lines available, for frozen French fries as well as packaged French fries for shelves. And there are also different kinds of machines for processing line of French fries. So the prices differ for each French fries line or even different machines.However,whatever manufacturing plants you want for your fries, you can always enjoy a competitive price from us without comprising on quality. To get the exact prices, you can contact us with your desired solutions.

French Fries Production Line Manufacturer

Gelgoog machinery is a professional designer and manufacturer of French fries plant. With great expertise and dedicated workers, our company are dedicated to constant innovations, improving our technology to make even better French fries making machines. We are customer-oriented company, regarding the needs of customers as our priority. French fries processing line in our company consists of whole set of machines, which are all made of high quality stainless steel to meet hygienic standards. All the potatoes are processes carefully in each process, ensuring high yield of premium French fries. As a reliable manufacturer, we can also offer customized solutions for your French fries production line. For a reliable process line is a great factor for the success of your French fries making business.