Potato chips frying machines are key equipment for producing potato chips. The potato chips frying machines price of different types on market vary greatly, usually affected by equipment type, function, scale and technology. This article will analyze the prices of several common types of potato chips frying machines to help companies and investors better understand the market situation.

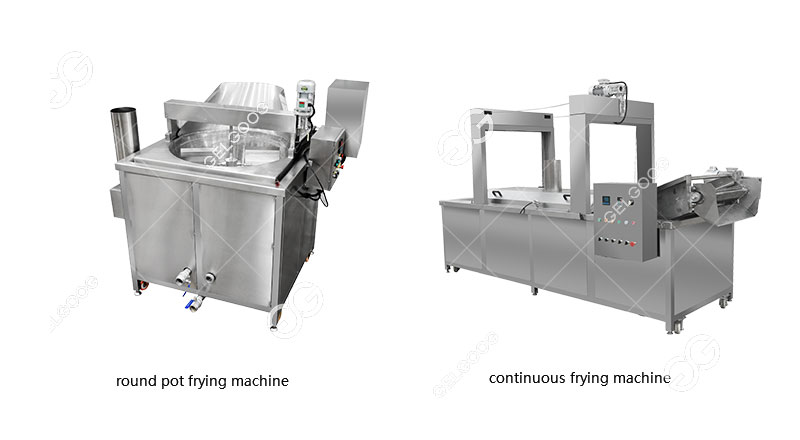

- Continuous frying machine price range: $10,000 – $20,000

This machine uses a continuous production method to fry potato chips efficiently and stably. This type of equipment usually has an automated control system that can adjust the oil temperature, oil volume and time to ensure the uniformity and stability of the potato chips quality. Due to its high degree of automation and higher production efficiency, it is suitable for large-scale production. The potato chips frying machine price is affected by production capacity, automation level and additional functions. High-end models are equipped with more advanced control systems and stronger frying efficiency, so the price will be higher.

- Round pot frying machine price range: $3,000 – $10,000

This machine is a traditional frying equipment, usually using a frying pan and a fixed temperature control system, suitable for small and medium-sized enterprises or start-ups. The operation of the fryer is relatively simple, and the oil temperature and time can be adjusted according to demand. Because the equipment is relatively simple and the operation is flexible, it is suitable for mass production.

- Basket frying machineprice range: $3,000 – $7,000

The frying machine usually has a basket structure and adopts semi-automatic operation, which can adapt to the production of potato chips of different specifications. It is suitable for small-scale production, and enterprises can customize it according to production needs.

Analysis of factors affecting the price of potato chips frying machine:

Production capacity: The greater the production capacity, the higher the price of the equipment. Large-scale production fryers are usually more expensive than small-scale frying.

Automation: Fully automated frying machine are more expensive than manual or semi-automated fryers. Automated frying machine can accurately control temperature, time and oil volume, reduce manual intervention, and improve production efficiency and product consistency.

Materials and technology: The material and technology content of the frying machine also affect the price. Highly corrosion-resistant materials, high-efficiency heating systems, energy-saving technologies, etc. will increase the cost of the equipment.