If you’re in the potato chip business, you know how important it is to produce high-quality chips that look and taste great. But one of the biggest challenges in chip production is achieving consistency in the thickness and shape of the slices. Unevenly sliced potatoes can result in chips that are too thin, too thick, or have uneven textures, which can make them less appealing to customers.

Fortunately, there are several types of equipment available that can help you achieve greater consistency in your potato chip production. One of the most important pieces of equipment is a potato slicer, which is used to cut potatoes into thin, uniform slices that can then be fried to create crispy, delicious chips.

There are several different types of potato slicers available, each with its own advantages and disadvantages. Here’s a brief overview of some of the most common types of potato slicers:

Handheld potato slicers: These are small, handheld devices that are used to manually slice potatoes into thin slices. They are affordable and easy to use, but they can be time-consuming and may not be able to produce slices that are consistent in thickness.

Mandoline slicers: These are slightly larger slicers that are used to slice a variety of fruits and vegetables, including potatoes. They are more precise than handheld slicers and can produce very thin, even slices. However, they can be difficult to clean and may require some practice to use effectively.

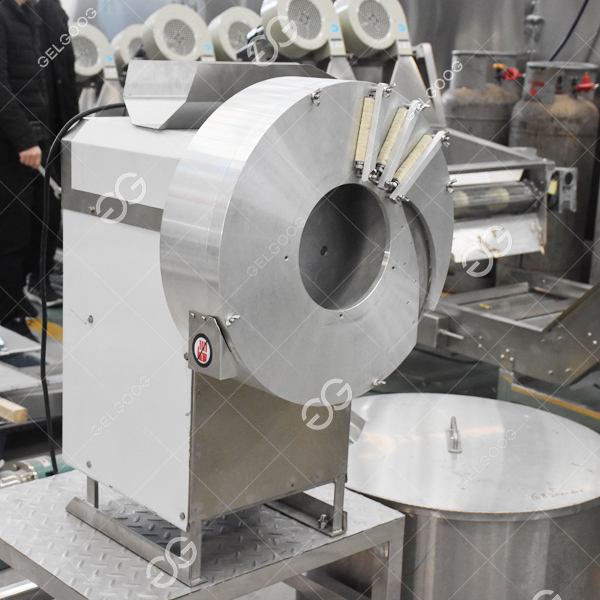

Automatic potato slicers: These are larger, more expensive machines that are designed specifically for slicing potatoes. They can be used to slice large quantities of potatoes quickly and efficiently, and they can produce very consistent slices. However, they require more space and maintenance than other types of slicers.

When choosing a potato slicer, it’s important to consider your specific needs and budget. If you’re just starting out in the potato chip business, a handheld or mandoline slicer may be a good choice, as they are more affordable and can still produce good results. However, if you’re producing chips on a larger scale, an automatic slicer may be necessary to keep up with demand.

In addition to using the right type of slicer, there are several other things you can do to ensure greater consistency in your potato chip production:

Use high-quality potatoes: The quality of your potatoes can have a big impact on the consistency of your chip production. Look for potatoes that are firm, evenly shaped, and free from blemishes or rot.

Maintain your slicer: No matter what type of slicer you’re using, it’s important to keep it clean and well-maintained. Regular cleaning and sharpening can help ensure that your slicer is producing consistent slices.

Monitor your slicing: When using a slicer, it’s important to pay attention to the thickness and shape of the slices. If you notice that your slices are uneven, adjust your slicing technique or the slicer itself to achieve greater consistency.

By using the right equipment and following these tips, you can achieve greater consistency in your potato chip production and produce chips that look and taste great. With consistent, high-quality chips, you can build a loyal customer base and grow your business over time. If you have any problem you can contact us freely. We are professional on the potato chips processing business. Email:wendy@machinehall.com phone/whatsapp:+8618539931566