Dans la production moderne, la machine à frire est un outil indispensable pour de nombreuses usines de transformation des aliments. Il existe de nombreux types de machines à frire. En fonction des différents besoins de production, les fabricants choisissent l'équipement approprié pour améliorer l'efficacité de la production et la qualité des produits. Cet article présente plusieurs types courants de machines à frire, notamment les friteuses à panier, les friteuses à pot rond et les friteuses en continu.

1. Machine à frire à panier

Les friteuses à panier sont généralement divisées en plusieurs zones de friture pour le traitement par lots de différents types d'aliments. Le principe de fonctionnement de ce type de friteuse est le suivant : en plaçant les aliments dans le réservoir d'huile, l'huile chaude entre rapidement en contact avec les aliments et les fait frire uniformément.

Avantages :

Économie d'énergie et haute efficacité : La friteuse à panier chauffe uniformément et peut terminer le processus de friture en peu de temps.

Grande flexibilité : Adapté aux besoins de production de petits lots et de variétés multiples, il permet d'ajuster la durée et la température de friture.

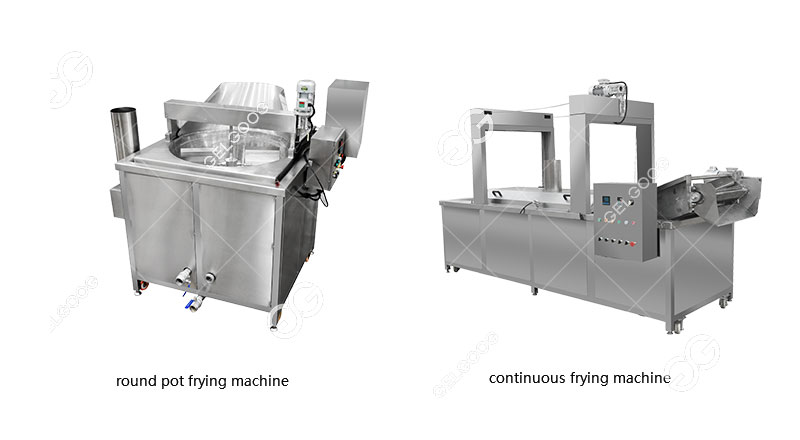

2. Machine à frire à pot rond

La friteuse à pot rond est un équipement de friture traditionnel, généralement composé d'un pot rond et d'un système de chauffage automatique. Sa conception avec fonction de brassage permet de chauffer uniformément les aliments et de réduire les fluctuations de température pendant la friture.

Avantages :

Forte stabilité : La forme ronde du corps de la marmite permet d'améliorer efficacement la stabilité de la température de l'huile, de réduire les fluctuations de la température de l'huile pendant la friture et d'assurer une friture homogène des aliments.

Large gamme d'applications : Convient à une grande variété d'aliments et peut répondre à différents besoins de production.

Fonctionnement simple : Le degré d'automatisation est élevé et le fonctionnement est relativement aisé.

3. Machine à frire en continu

La friteuse en continu est un équipement de friture à grande échelle couramment utilisé dans la production moderne. Cet équipement présente les caractéristiques d'une alimentation, d'une friture et d'un déchargement continus, et peut réaliser une production automatisée à long terme et à grande échelle. Son réservoir de friture est généralement long et équipé d'un système de chauffage et de contrôle de la température à plusieurs niveaux.

Avantages :

Haute efficacité : Grâce à ses caractéristiques de fonctionnement continu, il permet d'améliorer considérablement l'efficacité de la production et de réduire les coûts de main-d'œuvre.

Stabilité et cohérence : Le fonctionnement continu à long terme permet de maintenir la constance de la température de l'huile et la qualité du produit.

Haut degré d'automatisation : L'ensemble du processus de production présente un degré élevé d'automatisation, de l'alimentation au déchargement, qui peut être automatisé, ce qui réduit considérablement l'erreur de l'opération humaine.

Différents types de machine à frire sont adaptés à différentes échelles de production et à différents besoins. Vous pouvez nous faire part de vos besoins de production et nous vous recommanderons le type de produit qui vous convient.