Berapa harga mesin penggorengan keripik? Harganya bervariasi sesuai dengan kebutuhan produksi dan kebutuhan peralatan yang berbeda. Kisaran harga perkiraan adalah 5000USD-20000USD. Harga perlu dikonfirmasi berdasarkan konfigurasi peralatan, tingkat otomatisasi, dan faktor lainnya.

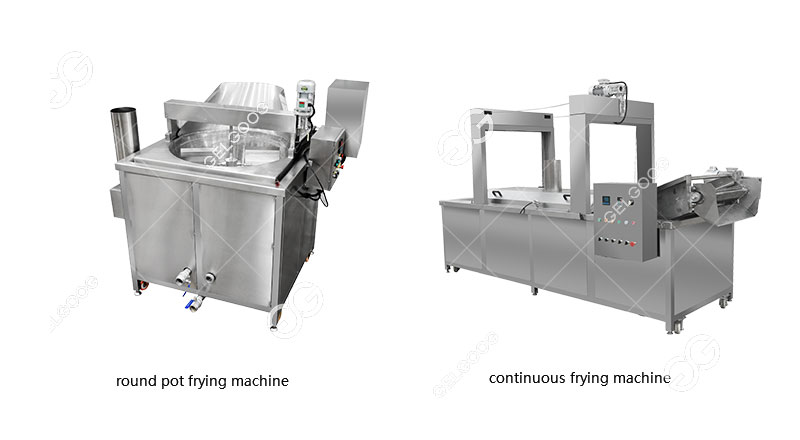

Jenis peralatan: Penggorengan keripik kentang yang umum digunakan adalah penggorengan batch dan penggorengan kontinu. Penggorengan batch cocok untuk produksi kecil dan menengah dan harganya relatif murah; sedangkan penggorengan kontinu cocok untuk produksi skala besar dan lebih mahal.

Kapasitas produksi: Kapasitas penggorengan biasanya diukur dalam hal output yang diproses per jam. Semakin besar kapasitasnya, biasanya semakin tinggi harga peralatannya.

Bahan dan konfigurasi: Penggorengan yang terbuat dari bahan berkualitas tinggi seperti baja tahan karat memiliki daya tahan dan kinerja higienis yang lebih baik, serta harganya relatif mahal. Selain itu, konfigurasi seperti tingkat otomatisasi, sistem kontrol suhu, dan perangkat keamanan juga akan memengaruhi harga.

Penggorengan batch:

Struktur sederhana: biasanya terdiri dari panci bundar, alat pemanas, sistem kontrol suhu dan alat pengaduk, mudah dioperasikan dan dirawat.

Pengoperasian yang fleksibel: cocok untuk produksi batch kecil, dapat dengan cepat mengganti bahan yang berbeda, dan beradaptasi dengan berbagai kebutuhan penggorengan.

Kontrol suhu yang tepat: dilengkapi dengan sistem kontrol suhu untuk memastikan suhu minyak yang stabil, meningkatkan efek penggorengan dan keamanan makanan.

Pemanasan yang seragam: Desain panci bundar membuat distribusi panas menjadi seragam, memastikan bahwa bahan-bahan dipanaskan secara seragam dan kualitas produk jadi stabil.

Tapak kecil: cocok untuk lingkungan produksi dengan ruang terbatas, mudah dipasang dan dipindahkan.

Produksi yang efisien: Dapat beroperasi secara terus-menerus, cocok untuk produksi skala besar, dan secara signifikan meningkatkan efisiensi produksi.

Otomatisasi tingkat tinggi: Ini mewujudkan otomatisasi dari pengumpanan hingga pemakaian, mengurangi intervensi manual, dan meningkatkan stabilitas produksi.

Sistem penyaringan oli: Biasanya dilengkapi dengan sistem penyaringan dan sirkulasi oli otomatis untuk memperpanjang masa pakai oli dan mengurangi biaya produksi.

Keamanan tinggi: Kamera ini dilengkapi dengan berbagai langkah perlindungan keselamatan, seperti perlindungan panas berlebih dan daya mati otomatis, untuk memastikan pengoperasian yang aman.

Kemampuan beradaptasi yang kuat: Dapat menangani beragam bahan dan cocok untuk berbagai kebutuhan pemrosesan makanan.